HMR Supplies manufactures SPMTs

HMR Supplies engineers recently designed and manufactured a pair of SPMTs for a ship builder in the Great Lakes. The company needed to move large ship sections from one production facility to the next within the shipyard as the ship builder was using unconventional methods to move heavy sections between facilities. HMR Supplies provided the solution of a pair of SPMTs so the sections will move easily around the shipyard and maneuver into tight spaces safer and faster.

The two self-leveling SPMT units were designed with the following specifications:

- 14’ wide X 16’ long (each unit)

- Six knuckles

- Stroke height of 18 inches

- 20,000lb axle capacity

- Gross load of 60 ton per unit

- 70˚ turning

- Two modes of steering – crab and articulating

- 65 HP Kubuta diesel engine

- RF wireless remoteEach SPMT unit the HMR Supplies engineering team designs is custom manufactured to meet the needs and purpose of the client project. Recent project analysis and workflow improvements allow the company to produce quality, effective products in a short amount of time.A familiar high profile SPMT project designed and manufactured by HMR Supplies is the 911-memorial tree mover, or straddle mover in New York City. In addition to SPMTs, HMR Supplies is a leading manufacturer of dollies, and has sold the Holland Dollie® since 1981. The product line includes power units, power dolly, air dolly, crane boom dolly, dual lane transporters and many more custom engineering solutions in the heavy haul transportation, marine and aerospace industries.Contact us if you are interested in learning more about SPMTs.

New Product – Holland Maxer

HOLLAND MAXERTM Trailer for Crawler Cranes

The Holland MaxerTM trailer is the solution to haul your crawlers faster and for less expense. Time is money and you will be down the road faster and easier with the Holland MaxerTM.

Features & Benefits

- Four or five axle configurations

- This creates the ability to meet tighter road restrictions

- Use a three or four axle tractor to pull

- Optional sixth and seventh axle configurations for extreme axle requirements

- Caster axles with locks

- Improved maneuverability

- Increased tire life

- Lift axles for

- Maximum onsite maneuverability by raising axles to shorten the turning radius

- Allows easier maneuvering for narrow driveways or access roads

- Saving money, fuel economy, and tire wear by lifting unused axles while empty traveling down the road

- Larger ground clearance than lowboys – this prevents trailers “getting hung up” while maneuvering

- Stable suspension for high center of gravity load

- Heavy duty 25,000 lbs. axles and suspension

- High strength alloy chains and hooks for tying down – less chains means less time wasted securing and un-securing loads

- Built in pull out access steps

Options

- Optional power tower with limited tilting fifth wheel plate for rough sites requiring more clearance and oscillation

- Optional manual tower with limited tilting fifth wheel plate to adjust for different truck heights and giving more clearance on rough sites

- Air scales for axle weights

- Storage boxes for remotes, rigging, and other crawler setup items

- Storage locations for outrigger floats for self assembling crawlers

Call today, 641-585-3630 for an estimate on a HOLLAND MAXERTM trailer!

A Project for NASA

Our team has designed and manufactured custom solutions for several large-scale projects: the 911 Memorial tree planting system, the launch of a 215 ft long super yacht, and adding mobility to one of the largest mobile stages in North America.

Our most recent project required HMR Supplies to mobilize an engine section for transport of NASA’s new rocket. Four 55T Holland Dollies and a Holland power unit were used to safely transport the engine. The engine section was loaded onto a barge at the Michoud Assembly Facility in New Orleans then traveled 1,240 miles by river to NASA’s Marshall Space Flight Center in Huntsville, Alabama.

The size of this engine section is huge, check out the image provided by NASA. Read more about the NASA Project here.

Call us today at 641-585-3630 to talk to an engineer about your next project.

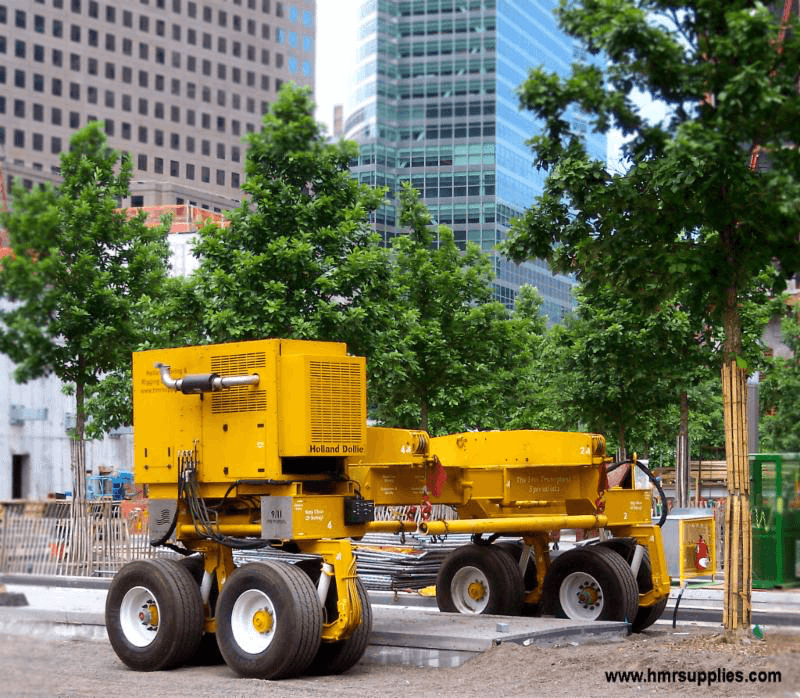

HMR Supplies – 911 memorial

Remote Controlled Load Transport System

HMR Supplies completes several large projects every year. A few years ago, our team designed a custom remote controlled tree setting system for planting tress at the 911 memorial. In 2014, we received the patent for this piece of equipment.

HMR Supplies designed the Straddle Mover (a remote controlled load transport system) to meet the special needs of planting trees on the 9/11 Memorial plaza. It was important for the equipment to be able to carry the tree in the center of all the axles, be capable of traversing sideways and able to negotiate openings on the surface of the plaza. There are also up to 8 stories underneath the plaza for access, equipment and a museum requiring low ground pressure and a wider tire base.

When you see the Straddle Mover up close, on the 9/11 Memorial webcam or on YouTube, it is an impressive site. The knuckle suspension is able to lift and lower the frame and load up to 20 inches. The block and cable system is capable of lowering the load below ground level, and 135 degrees of steering allows the Straddle Mover negotiate the tight quarters on the plaza. A single operator and a remote control operate the straddle mover.

Although the Straddle Mover was originally designed for moving trees, it can also be used for a variety of applications.

Creating solutions for custom projects is what we do best. Call us for a quote on your next project. 641-585-3630